SWITZERLAND

Meto-Fer Automation AG

Maienstrasse 6

CH-2540 Grenchen

Phone: +41 32 654 57 57

Fax: +41 32 654 57 60

e-mail: info@meto-fer.ch

USA

mf automation, Inc.

355 Wyoming Street

Pittsburgh, PA 15211-1739 USA

TOLL FREE (in the US): 1-888-METO-FER

Phone: 412-488-3488

Fax: 412-488-3498

e-mail: info@meto-fer.com

Follow this link to learn about our innovative Chain Pallet Transfer System.

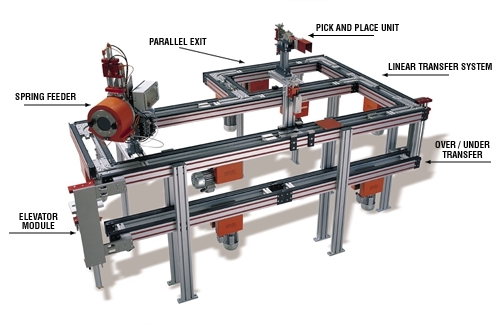

Modular Linear Transfer Systems: MP System

(To view a larger image of the above photo, please click here.)

Modular components crafted for flexibility and reliability. Standard pallet sizes 100 x 100mm up to 500 x 500mm

Global competitiveness is determined not only by the cost-performance-ratio, but more and more by the level of assembly efficiency and the ability to rapidly adapt to market changes.

Designed with flexibility as a key factor, the MP System consists of standard modules, each of which operates autonomously, yet can be joined with other standard modules to form a complex linear assembly system. Because the modules are standardized, they can be interchanged quickly and easily, resulting in fast implementation of a new or expanded assembly system if new or altered tasks are required. The standard modules of the MP System can be reutilized 100%!

The MP Modular Linear Transfer System by Meto-Fer®

The MP Modular Linear Transfer System by Meto-Fer®

FEATURES

- Interchangeable modular elements

- A variety of standard modules allow you to determine machine configuration

- Supports manual, semi-automatic or fully automatic operation

- Easily expanded

- Manual work modules can be directly integrated as needed

- Modules operate autonomously

- Two-belt system moves pallets in a linear direction

- Module type stations can be added lengthwise or crosswise as needed

The user-friendly modular design of the MP System guarantees flexibility

and enables quick reaction to changing market demands. Thus, an investment in flexible automated assembly is not only rewarding

technically, but economically as well.

The user-friendly modular design of the MP System guarantees flexibility

and enables quick reaction to changing market demands. Thus, an investment in flexible automated assembly is not only rewarding

technically, but economically as well.

The pallets with the work piece carriers are controlled and indexed, allowing transport of the pallets that is independent of a cycle. Between single modules, any reserve of the pallets is possible. Each module has its own actuation, separating, and positioning.

Another key to the flexibility of the MP System is that it allows a step-by-step adaptation to future needs. Thus, to minimize production stops, the assembly system can first be designed with several manual work modules. Then through step-by-step automation of the assembly, the manual work modules can eventually be replaced by automated modules.

ADVANTAGES TO MODULAR DESIGN

- Can be used for very simple or very complex assembly solutions

- Change, readjustment, lengthening or shortening of existing assembly machines can be accomplished quickly

An optimal solution to an assembly problem requires both technical prowess and economic benefits. The MP System affords the designer optimum efficiency in both respects. Because of the standardized design of the modules, they can be exchanged and completely reutilized.

Because the MP System is future-oriented by design, your most stringent industry requirements for cost-effectiveness, flexibility, high quality and fast processing time are all fulfilled.

We welcome any comments or questions. If you require information not available at this web site, or if you have questions about our products and their capabilities, please contact your nearest Meto-Fer® distributor or use the information below. CAD drawings of many Meto-Fer® products are available in AutoCad formats.

To request more information about our products, please use our online information request form.

A complete line of automation components

Our product offering includes pneumatic automation components, pneumatic linear components, pneumatic linear units, linear slides, vertical components, vertical modules, vertical units, elevating tables, standard roller slides, X-Y linear components, ball screw x-y tables, ball screw linear components, alignment slides, precision miniature linear actuators, rotary actuators, rotary actuator components, rotary gripper heads, mini linear actuators, miniature robotic grippers, modular compact grippers, angular motion grippers, semi-parallel motion grippers, parallel motion grippers, gripper automation components, oil cushions for automation components, elastomer cusions for automation components, flow controls for automation components, vacuum units for industrial automation components, suction cups for industrial automation components... a wide variety of quality pneumatic components for many industrial automation applications.